What is PAT?

PAT is the abbreviation for Process Analytical Technology. In conventional reaction analysis, it was common practice to conduct sampling either during or after the reaction, and then analyse and/or take measurement of the samples using the equipment such as HPLC, GC and NMR. Nowadays, the technology used to analyse the progress condition of the reaction in real-time has been developed further. At our company, we have installed various kinds of PAT-related equipment which enables us to collect and analyse accurate experimental data efficiently and scientifically.

写真提供:メトラー・トレド株式会社

Automatic synthesis

Thanks to Easy Max®, the reaction can be controlled automatically. By setting up the addition of reagents, controlling the internal temperature, stirring time, etc., Easy Max® synthesises the target compounds by controlling the reaction parameters automatically.

Accurate measurement data can therefore be obtained precisely and without any human error. ReactIR®, Particle View® and Particle Track® can be combined with this equipment to conduct all different kinds of measurements simultaneously.

写真提供:メトラー・トレド株式会社

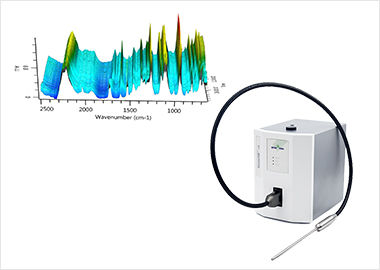

IR real-time measurement

With ReactIR® it is possible to measure IR in real-time by inserting a probe directly into the reaction solution. During the reaction process, we analyse the reaction by reading the peak IR value to examine how the starting material, reaction intermediate, target compound and the by-products are increasing or decreasing.

写真提供:メトラー・トレド株式会社

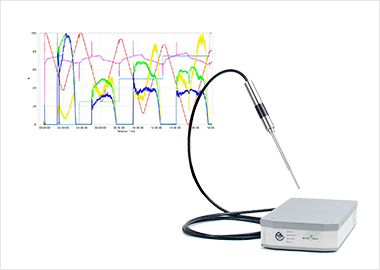

Observation of the crystal form in the solution

Particle View® checks the state of the solution in real-time by taking a photograph while a probe is directly inserted into the solution. Since this helps us to understand the process of crystallisation, we use this equipment to control crystal polymorphism.

In addition, it is also used to measure the solubility by controlling the temperature and concentration as well as to observe precipitation of the crystals and the dissolution conditions.

写真提供:メトラー・トレド株式会社

Measuring the crystal size and number of particles

Particle Track® measures the particle size and its quantity in the reaction solution in real-time. This enables us to examine and determine the optimum conditions of crystallisation.

Development of APIs using PAT

We use PAT-related equipment to examine the reaction conditions and crystallisation state. The use of PAT enables us to observe and understand the reaction conditions and crystallisation process over time. As a result, we can set up the manufacturing conditions effectively and scientifically and are therefore able to develop high-quality APIs in the short term.

Contact us

Contact us Request documents

Request documents